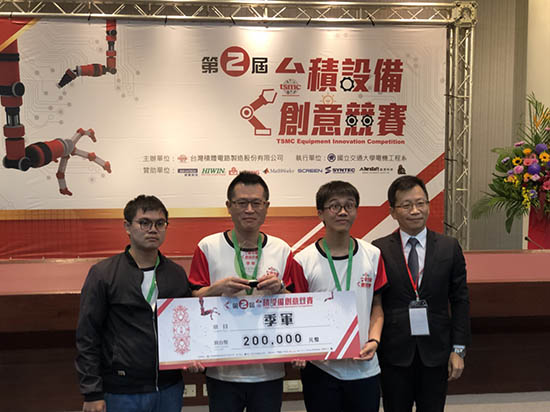

The team "Taiwan Industry 4.0 Exploration 2.0," formed by graduate students and undergraduate students from the Department of Mechanical Engineering and the Department of Electronic Engineering, Southern Taiwan University of Science and Technology, won 4th place and NT$ 200,000 in the second TSMC Equipment Innovation Competition, organized by the TSMC and the Department of Electronic Engineering, National Chiao Tung University.

【The team "Taiwan Industry 4.0 Exploration 2.0" from Southern Taiwan University of Science and Technology won 4th place and NT$ 200,000in the second TSMC Equipment Innovation Competition. The team members include (left to right) graduate students Zheng-Bang Shi, Chi-Rui Lin, and Jun-Wei Huang.】

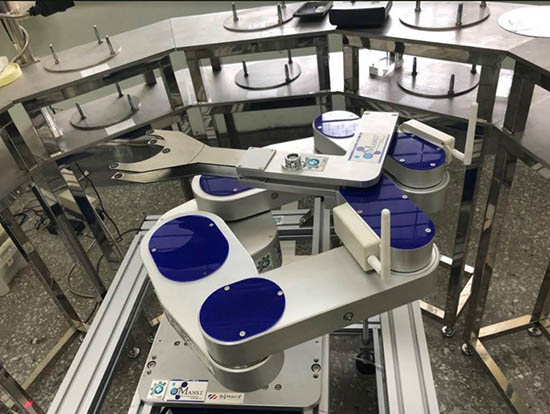

The equipment innovation competition of TSMC was mainly based on the transmission of semiconductor equipment wafers. All the teams were required to create a semiconductor robot arm to complete their tasks in a manner that was fast, stable, and accurate. The update enhancement of the competition included the defect detection of wafer AOI image, the signal communication of the process equipment, and the control of robot arm, which made the competition closer to the current situation of TSMC's factory and increased the difficulty of the competition.

【The semiconductor robot arm created by "Taiwan Industry 4.0 Exploration 2.0"】

"Taiwan Industry 4.0 Exploration 2.0" is formed by graduate students Zheng-Bang Shi, Chi-Rui Lin, and Jun-Wei Huang and directed by Prof. Yu-Chun Du of the Department of Electronic Engineering. They have had brilliant performances in in the TSMC Equipment Innovation Competition for two consecutive years. In addition to rapidly completing the tasks required by the competition, the robot arm they created successfully overcame the difficulties that they had to complete the wafer defect detection, process flow control tasks, and integrate the functions into the system. The innovative intelligent vibration sensor developed by the team has the advantages of high sensitivity and simple installation, which can monitor the arm condition and feedback control by wireless transmission. The measured results are quite good and stable. Over the past six months since the competition team participated in the competition, the team developed from correcting their direction to understanding the requirements of the new tasks, from facilitating the signal communication of processing equipment to rectifying the arm control and movement correction, until they passed the final wafer AOI image defect detection.

They overcame difficulties step by step, with great communication and creativity in their interdisciplinary cooperation.

President Deng-Maw Lu of Southern Taiwan University of Science and Technology said that the National Taiwan University of Science and Technology attaches great importance to the cross-disciplinary cooperation of various departments, especially on the research topics of smart manufacturing. He hopes to cultivate a competitive next generation for Taiwan by engaging students in relevant competitions, cultivating their capabilities interdisciplinary cooperation and correcting their views of the industry as a whole.